There are currently many devices on the market that can capture physical objects in 3D. When choosing a device for 3D scanning, it is necessary to answer the following questions:

Thanks to the answers to the questions below, an experienced expert can advise you on which solution would be best for your application. The basic division of 3D scanners is as follows:

Touch scanners (CMM)

Non-contact laser scanners

Optical scanners

REVERSE ENGINEERING (RE)

The scanned data will be the template for creating a new CAD model.

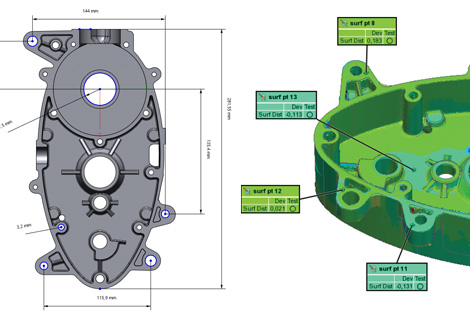

QUALITY CONTROL (QC)

With the help of a 3D scanner, we can verify whether the product is manufactured correctly.

3D PRINTING

The scanned 3D model can be immediately used for 3D printing.

FOR FURTHER DESIGN MODELING ("BUILDING")

A custom design of a new component can be created around the scanned data.

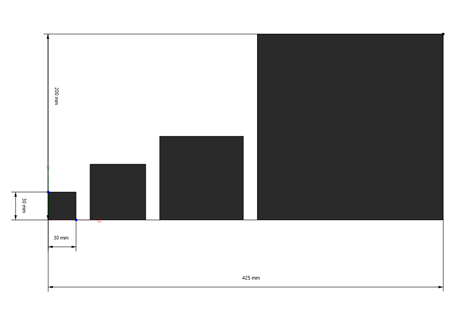

No 3D scanner can scan a part 2cm and 5m at the same time, collect data at the same speed and have accurate results.

It is therefore important to determine the size range of the parts to choose the right 3D scanner. If the wrong type of 3D scanner is chosen, the accuracy will deteriorate and the scanner will be more difficult to use.

3D scanners can be used to scan objects with a colored texture. These 3D models can then be used for video animations (presentations) and graphic works.

Devices that also detect color texture usually scan with less accuracy and are used in archaeology, design and heritage conservation.

Scanners with high accuracy do not capture the color texture and are used, for example, in engineering.

When choosing the right 3D scanner, we must also take into account the place (exterior, interior) where the device will be operated. In order to be able to scan outdoors with a 3D scanner, for example, it is necessary to choose the right object sensing technology.

Ambient temperature, vibration and lighting conditions must also be considered when scanning. When choosing, it is therefore necessary to set the selection criteria so that the device works with the specified accuracy.

When using the 3D scanner outside of its working conditions, accuracy may deteriorate or scanning may become impossible.

Creating a 3D scan of any object takes time. The time required depends on the required number of scanned objects per day.

During serial inspection, it is necessary to determine how much time the 3D scanner has to capture the necessary geometry.

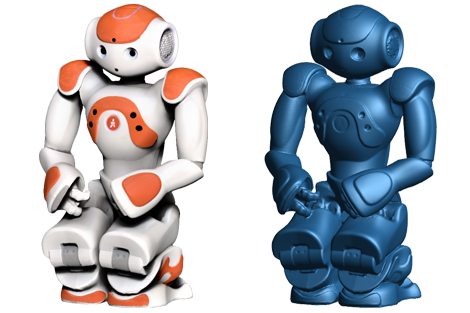

In the case of scanning the human body, it is necessary to scan the character as quickly as possible, since there is always slight movement of the character.

Not every software allows you to work with outputs from 3D scanners such as STL, OBJ, WRL,... When choosing a 3D scanner, it is therefore necessary to check your options. If the purchased software does not already support these formats, it will be necessary to think about choosing additional software for processing data from the 3D scanner.

There are many companies on the market that have been developing software for reverse engineering, quality control and 3D data processing for other applications for a long time. The main representatives of these companies are Creaform, 3D Systems, InnovMetric, Geomagic.