The Surface Damage module is a specialized software for the assessing of mechanical damages, such as corrosion and dents on complex and curved components. It directly integrates into VXintegrity, Creaform’s NDT 3D software platform. The Surface Damage module accurately measures the damage dimension based on the Industry interaction rule. The software includes advanced reporting options, such as automatic report generation and CSV file export of the digitalized surface thickness loss mapping.

Propane spheres are designed according to ASME Sec. VIII Div. which is one of the strictest design guidelines for this industry. Indeed, to maintain propane in its liquid form, the pressure has to be high, and a spherical design is the best to sustain such pressure. Deadliest incidents happening in refineries often involve such components.

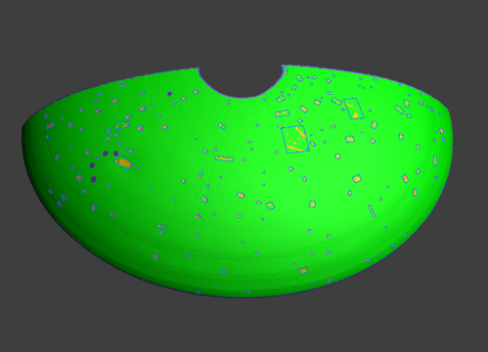

Our software module offers the best measuring tools on the market to assess corrosion on a spherical component. It is completely technician-independent and offers powerful residual thickness export capabilities.

ANALYSIS Tools

-Depth measurement using straight edge

-Reference with the Vxi Arrow.

-Interaction parameters

Excel Cells thickness export

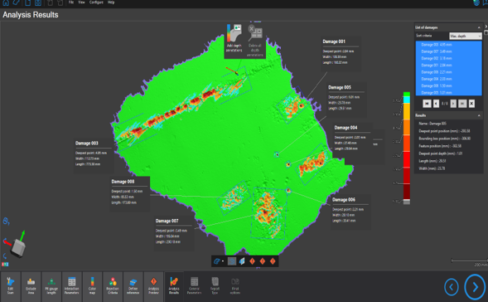

Because of their superficies, tank floors and roofs are often assessed using MFL equipment in a similar manner to Pipecheck with MFL Pig in the pipeline industry. Moreover, bulge damage on a cylindrical component of the tank can be assessed with this module.

Our software module offers the best measuring tools and precision on the market to assess external damages. The surface damage could be used not only to assess the damage on the surface, but also as the in-field reference to calibrate the MFL instrument.

ANALYSIS Tools

-Automatic maximum depth detection

-Automatic defect dimension

-Accuracy up to 0.02 mm

-Reference with the Vxi Arrow.

-Interaction parameters

-Global thickness excel export

-Excel Cells thickness export